Home » Projects » Shellfish Aquaculture Production and Management Projects » Advancement of Sunray Venus Clam Culture through Evaluation of Alternative Growout and Harvest Methods

Home » Projects » Shellfish Aquaculture Production and Management Projects » Advancement of Sunray Venus Clam Culture through Evaluation of Alternative Growout and Harvest Methods

To advance the production of a promising new aquaculture species in Florida, alternative farming technology was evaluated for the sunray venus clam Macrocallista nimbosa. Bottom planting under cover nets, a method used in other states for hard clam culture, may be more suitable for the sunray venus clam as opposed to bottom bags, which is the method typically used by Florida growers. To address the need for diversification and obtain full adoption of this alternative culture species by industry, the use of a pump-driven device was evaluated to harvest bottom-planted sunray venus clams. The effects on water quality and soil properties were examined and compared to harvesting sunray venus clams in bottom bags. Although clam farming in Florida occurs on designated aquaculture lease areas, there is warranted concern regarding the use of mechanical harvesting in coastal waters. While pump-driven harvesters are used extensively in other states, it was important to test this device under commercial conditions to determine extent and duration of potential environmental impacts.

Growout-sized seed (average 25 mm length) were bottom planted in quadruplicate under cover nets (9 mm polyester mesh netting, 8’x10’, 80 ft²) and in bottom bags (9 mm polyester mesh, 16 ft²/bag, belt of 5 bags, 80 ft² per replicate belt) at the UF experimental lease within the Dog Island Aquaculture Use Area near Cedar Key, FL during November 2012 and harvested approximately one year later. A “box” harvester in which a 5 hp pump delivers pressurized water via nozzles along a spray bar was used to harvest the bottom plants. At harvest, survival and growth characteristics of sunray venus clams for each culture method were determined. Product quality was also assessed to determine the effects of culture and harvest methods on shell deformities, shell breakage, meat grittiness, and shelf life in refrigerated storage.

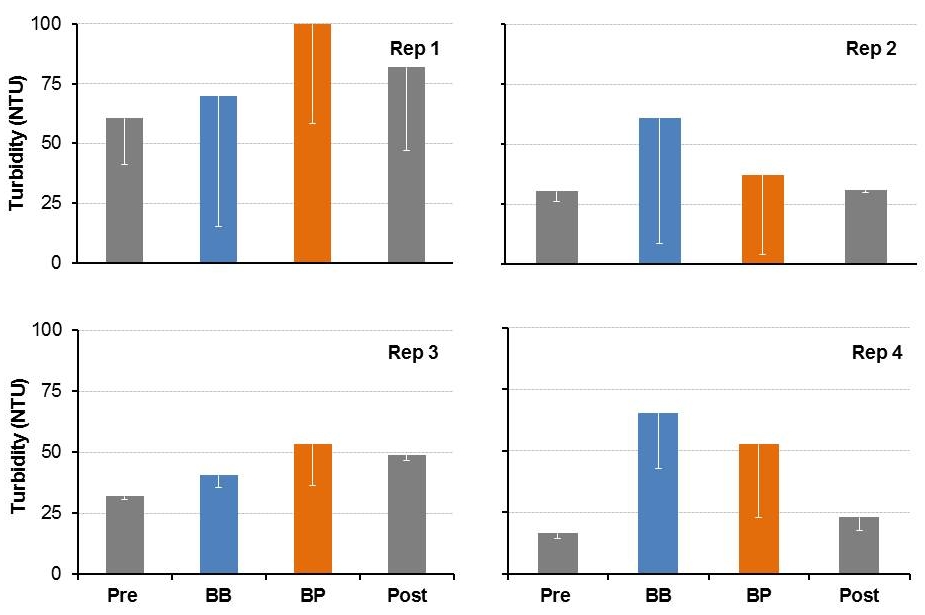

A Before-After, Control-Impact, Paired (BACIP) experimental design was used to obtain pre- and post-harvest data in the replicated field trials. The bottom bags were directly compared with the bottom plants and both culture methods were compared with reference (unfarmed) sites to differentiate natural changes from those caused by harvesting. Water quality parameters (temperature, salinity, dissolved oxygen, turbidity) were measured continuously (every minute) 48 hours pre- and post-harvest using four sondes positioned 5 feet in cardinal directions and one sonde positioned 25 feet downstream of each culture replicate. Subaqueous soils were sampled prior to planting, then repeatedly post-harvest at 0, 4, and 8 weeks to evaluate particle size (sand, clay, silt) and organic matter. Cross-sectional soil elevation profiles were also monitored to measure tracks created by harvest activities and their recovery over eight weeks. To accomplish this, PVC pipe arrays were pushed into the soil to a given depth, perpendicular to the track direction following harvest.

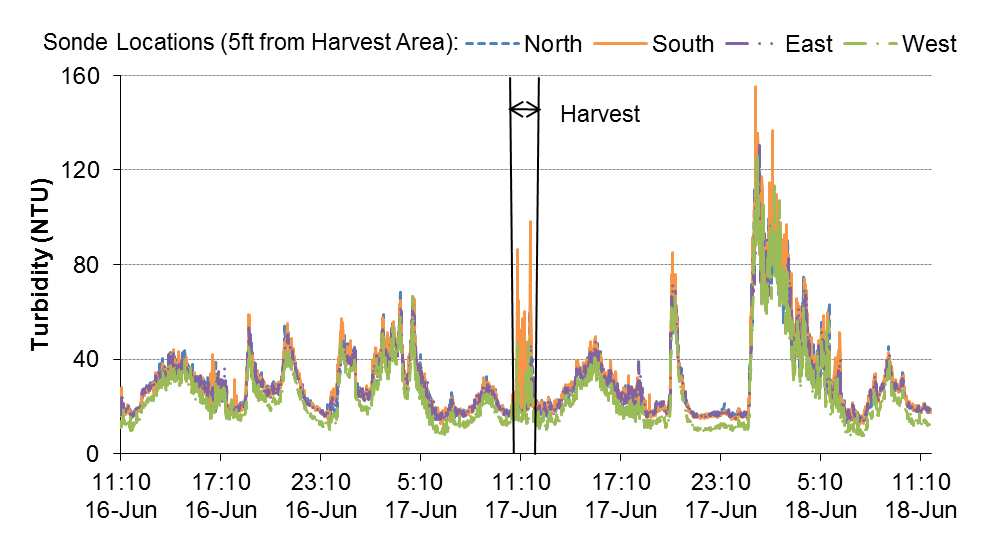

To determine the extent of a sediment plume created by the use of a pump-driven harvester in a commercial-scale application, an unfarmed area (without sunray venus planted) of 300 ft² was also tested within the UF lease. Turbidity was measured continuously for 24 hours pre-and post-harvest by positioning eight sondes 5 and 25 feet from the mid-points of the test plot in cardinal directions. Three additional sondes were deployed 45 feet downstream of the plot, 20 feet apart.

Production: Survival of sunray venus clams was the same for both culture methods (47-48%); however, growth was statistically different as sunray venus cultured using the bottom plant method were larger (61.9 mm length, 21.2 mm width) and heavier (29.9 grams total weight, 8.3 grams meat weight) than those cultured in bottom bags. Yield was increased by 80% using bottom plants (1.8 lb/ft²) versus bottom bags (1.0 lb/ft²). Assuming a potential market size of ~50 mm shell length, the culture period could be reduced by 3-4 months using the bottom plant method, potentially lessening the risks associated with mortalities and increasing survival.

Product Quality: Product quality of sunray venus clams harvested from bottom plants was not compromised as shell deformities (0.5%), shell breakage (2.9%), meat grittiness after 48 hours of purging (0.3 rating based on a scale of 0-4), and shelf life in refrigerated storage (100% survival after 10 days) did not differ statistically when compared to sunray venus clams harvested in bottom bags (3.1% deformities, 0.5% breakage, 0.3 grittiness rating, 100% survival).

Water Quality: Values for temperature, salinity, and dissolved oxygen did not differ during harvests of the two culture methods. Only turbidity (a relative measure of water clarity) showed any noticeable difference with respect to background condition. On average, turbidity appeared higher during the harvest of bottom plants (248 NTU maximum value) and bags (186 NTU maximum value) than the pre-harvest and post-harvest intervals; however, statistical differences were only noted in two of the four replicates. In comparing the harvest methods, mean turbidity values obtained during the use of the pump-driven harvester (average of replicates, 59.7 NTU) did not statistically differ from those of the bag harvests (average of replicates, 60.4 NTU). Impacts of harvesting activities to the water column were short-term as turbidity values returned to background levels within 5-9 minutes post-harvest.

Soil Properties: Particle size and organic matter content did not differ between harvest or reference (unfarmed) sites at harvest (0 weeks) and 4 weeks post-harvest. At 8 weeks post-harvest, sand content was higher and fines (clay + silt) were lower at bottom bag sites in comparison to bottom plant and reference sites. Consistent changes over time among treatments suggested that natural processes were far more active in sorting soil particle size than were the methods of harvest. Although tracks created by the pump-driven harvester were significantly different than those created by harvesting bags, the depths were shallow (-3.75 cm) after harvest and continued to recover over the 8-week monitoring period (-1.59 cm).

Commercial-scale Harvest: The mean turbidity associated with harvest activity was significantly lower than the pre-harvest means at all but the closest sonde (5 feet downstream). The post-harvest means at all sonde distances suggesting natural events can exceed turbidity produced from harvest activity. An example of this occurred at approximately 13 hours post-harvest as turbidity values generated by a summer squall (16 knot ESE winds) were two times higher at all sondes than those during harvest. Overall, turbidity values observed in the commercial trial were lower than similar activities during the replicated field trials. This finding was attributed to differences in environmental conditions due to higher water levels (2.2-2.7 ft) during the commercial harvest versus <1.0 ft during the field trials. Based on these observations, maximizing water depths and avoiding harvests on spring tides, whenever feasible, may mitigate turbidity events.

Summary: These findings consistently supported results found in numerous published studies, which conclude that the physical, biological, and chemical effects of mechanical harvesters are generally short-lived with the rate of recovery varying among studies. The observed effects in this study were often indistinguishable from ambient levels or natural coastal estuarine variability. The most obvious effect (sediment plume) ceased when harvesting was completed. This study was initiated upon on a request from the Florida Clam Industry Task Force in 2012 that research on alternative harvesting methods, which would minimize impacts to natural resources and potentially improve clam production, be conducted. The science provided by this research can be used in consideration of legislative and/or regulatory changes to allow for the use of pump-driven harvesters on shellfish aquaculture leases.

Project results were presented at a state and national meeting. The presentation and final report below can be viewed in PDF format.

Advancement of Sunray Venus Culture through Evaluation of Alternative Growout and Harvesting Methods (3.4 MB)

Sturmer, L., Osborne, T., White, W., and Ellis, R. 2015. Presented at the 107th meeting of the National Shellfisheries Association.

Advancement of Sunray Venus Culture through Evaluation of Alternative Growout and Harvesting Methods (3.0 MB)

Sturmer, L., Osborne, T., White, W., and Ellis, R. 2014. Final Report to the Florida Department of Agricultural and Consumer Services, 86 pp.

University of Florida | IFAS

Shellfish Aquaculture Research & Extension

11350 SW 153rd Court I P.O. Box 89

Cedar Key, FL 32625

Phone: (352) 543-5057