Home » Projects » Shellfish Aquaculture Production and Management Projects » Effects of Two Net Coatings in Reducing Biofouling for Florida Clam Culture Gear

Home » Projects » Shellfish Aquaculture Production and Management Projects » Effects of Two Net Coatings in Reducing Biofouling for Florida Clam Culture Gear

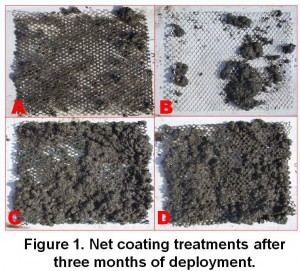

Net coating treatments (A, B, C, D) can be viewed after three months of deployment on a shellfish aquaculture lease (Figure 1). At three months, A and B (all net colors) had significantly less total wet weight (TWW) of biofouling than C (both colors) and D. Treatment B-Wht had less TWW than C-Grn and D. No treatments differed in percent fouling released (PFR) after agitation. At six months, treatments B-Blk and B-Wht had less TWW than A, C, and D. Treatment B-Red had less TWW than A and C (both colors). Treatment B-Blk had greater PFR than D. The average biofouling coverage of net coating treatments deployed for three months is illustrated in Figure 2. Coverage was defined as Not Fouled (NF), Tunicates (TC), and Detritus/Mud (D/M). The category Other (O) was not represented graphically due to low occurrence. Treatment B (all colors) had significantly more “not fouled” points than other treatments. Treatment A had less points fouled with TC than C and D, and more points fouled with D/M than others.

In summary, biofouling is a major impediment in all areas of extensive aquaculture, including shellfish farming. By reducing biofouling, we can improve equipment maintenance, reduce harvest labor, and may enhance stock performance. In this study, the advantages of two non-toxic, fouling release coatings were demonstrated. When compared to the industry standard coating (C) and untreated netting (D), Treatment A had variable performance with less total wet weight of biofouling at the three-month duration, but similar total wet weight of biofouling at the six-month duration. Treatment A also had similar biofouling coverage at the three-month duration.

Net coating treatments (A, B, C, D) can be viewed after three months of deployment on a shellfish aquaculture lease (Figure 1). At three months, A and B (all net colors) had significantly less total wet weight (TWW) of biofouling than C (both colors) and D. Treatment B-Wht had less TWW than C-Grn and D. No treatments differed in percent fouling released (PFR) after agitation. At six months, treatments B-Blk and B-Wht had less TWW than A, C, and D. Treatment B-Red had less TWW than A and C (both colors). Treatment B-Blk had greater PFR than D. The average biofouling coverage of net coating treatments deployed for three months is illustrated in Figure 2. Coverage was defined as Not Fouled (NF), Tunicates (TC), and Detritus/Mud (D/M). The category Other (O) was not represented graphically due to low occurrence. Treatment B (all colors) had significantly more “not fouled” points than other treatments. Treatment A had less points fouled with TC than C and D, and more points fouled with D/M than others.

In summary, biofouling is a major impediment in all areas of extensive aquaculture, including shellfish farming. By reducing biofouling, we can improve equipment maintenance, reduce harvest labor, and may enhance stock performance. In this study, the advantages of two non-toxic, fouling release coatings were demonstrated. When compared to the industry standard coating (C) and untreated netting (D), Treatment A had variable performance with less total wet weight of biofouling at the three-month duration, but similar total wet weight of biofouling at the six-month duration. Treatment A also had similar biofouling coverage at the three-month duration.  Upon further examination, we saw that Treatment A had significantly less tunicates (TC) but significantly more detritus/mud (D/M), likely accounting for the lower wet weight but similar biofouling coverage. Conversely, Treatment B performed well in terms of both total wet weight of biofouling organisms and biofouling coverage for both durations when compared to C and D. Although net color was examined, no significant trends were detected. No differences in percent fouling released through agitation may be attributed to methodology; an increase in replication coupled with a standardized technique may help identify fouling release advantages of the experimental net coatings. The performance of both fouling release coatings was encouraging and warrants future research of their application in shellfish aquaculture.

Presentations (poster) on project results were made at state and national meetings and can be viewed below in PDF format.

Upon further examination, we saw that Treatment A had significantly less tunicates (TC) but significantly more detritus/mud (D/M), likely accounting for the lower wet weight but similar biofouling coverage. Conversely, Treatment B performed well in terms of both total wet weight of biofouling organisms and biofouling coverage for both durations when compared to C and D. Although net color was examined, no significant trends were detected. No differences in percent fouling released through agitation may be attributed to methodology; an increase in replication coupled with a standardized technique may help identify fouling release advantages of the experimental net coatings. The performance of both fouling release coatings was encouraging and warrants future research of their application in shellfish aquaculture.

Presentations (poster) on project results were made at state and national meetings and can be viewed below in PDF format.

University of Florida | IFAS

Shellfish Aquaculture Research & Extension

11350 SW 153rd Court I P.O. Box 89

Cedar Key, FL 32625

Phone: (352) 543-5057