Purpose:

Hard clam aquaculture has developed rapidly in Florida as well as in other states in the Southeast U.S. Adequate seed availability is a major industry concern and has, in recent years, faced critical shortages coupled with increased prices. Remote setting of hard clam,

Mercenaria mercenaria, seed would allow growers to become less dependent upon traditional seed sources, potentially reduce the cost of seed, and help ensure a greater chance of success by incorporating another step into their existing business. This would enhance the continued economic viability of clam farming, a significant and growing sector of Florida’s aquaculture industry.

Approach:

The goal of this study was to test a technology that may help ensure a reliable and consistent supply of high quality and inexpensive clam seed to growers, thus fostering an emerging aquaculture industry by eliminating a seed shortage that limits sustainability. The overall objectives were to develop, test and demonstrate technical procedures and determine the financial feasibility of transferring remote setting technology from the Pacific Northwest molluscan shellfish industry to the hard clam aquaculture industry in Florida. Specific objectives of this project were to: 1) develop harvesting, refrigeration, packaging and shipping protocols for clam pediveliger larvae; 2) produce a minimum of 10 million pediveliger larvae, or pre-set clams, each project year for the large-scale evaluation of remote setting technology; 3) test the survival and growth of pre-set clam larvae for rearing to a 1-mm seed size in identical remote setting systems at two different locations in Florida after overnight refrigeration storage and shipment; 4) test two different management and feeding regimes at these nursery sites; and, 5) compare the costs of producing 1-mm hard clam seed in a remote set nursery facility to the market price associated with purchasing 1-mm seed from a commercial clam hatchery.

Results:

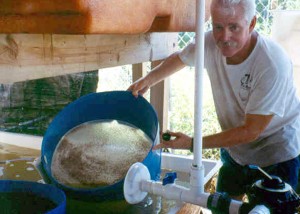

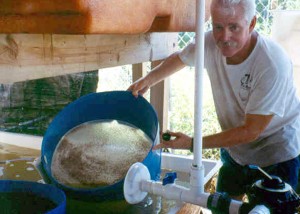

Technical procedures were developed and demonstrated during 2000 – 2001 at participating land-based nursery operations in New Smyrna Beach and Cedar Key. These facilities were modified to include: 1) 250-gallon weller tanks, 2) sand and bag filters for mechanical filtration of water supply, and 3) downwellers ranging in mesh size from 120 to 710 microns. Competent pediveliger larvae obtained from commercial hatcheries were placed on shipping material (moist coffee filters), refrigerated for 2-3 hours, packaged in shipping boxes with gel packs, shipped overnight, and delivered to remote set locations for evaluation of technique, site, and season. Management regimes evaluated over rearing trials included: 1) supplemental feeding with a commercial algal paste or cultured algae versus none, and 2) duration of shipping times. Procedures used at the test sites included: 1) stocking 3 million pediveligers per tank, 2) water flow of 2-5 gpm, 3) daily cleaning of seed and tanks, 4) cleaning filters 1-2 times daily, 5) changing wellers 2 times weekly, and 6) sieving seed on a weekly basis. Biological features documented included survival and time to reach a 1 mm seed, the minimum size typically reared at nurseries.

Results summarized from these rearing trials provide for operational procedures and guidelines for remote setting of hard clam seed.Production of 1 mm seed during spring 2001 ranged from 15 to 54% over a 7 to 10-week period. No differences were detected in duration of shipping times (2 versus 20 hours) but production doubled when algal paste was used versus no supplemental feeding. Production of 1 mm seed during fall 2001 ranged from 13 to 41% over a 5 to 8-week period. Supplemental feeding with cultured “live” algae versus an algal paste increased production by 70% at the New Smyrna Beach site; whereas production in Cedar Key using the algal paste was 3 times that obtained at the east coast nursery. In summary, hard clam pediveliger larvae were refrigerated and shipped up to 20 hours without detrimental effects. Setting success was not fully determined; but production to a 1 mm seed size averaged 27% in the 2001 field trials. The economic characteristics, including a cost budget and potential cost savings associated with remote setting, were described.

A number of presentations about project results have been made at state, regional, and national meetings. The presentation and report below can be viewed in

PDF format.

Investigators and Partners:

- Leslie Sturmer, University of Florida IFAS Shellfish Aquaculture Extension

- Chuck Adams, University of Florida IFAS Food and Resource Economics Department

- John Supan, Louisiana State University, Office of Sea Grant Development

- Cedar Creek Shellfish Farms, New Smyrna Beach, FL

- Cedar Key Raceways, Cedar Key, FL

- Sea-Ag, Vero Beach, FL

- Sea Perfect, SC

- Southern Cross Sea Farms, Merritt Island, FL

Funding:

- Florida Sea Grant College Program, 2000 – 2002

A number of presentations about project results have been made at state, regional, and national meetings. The presentation and report below can be viewed in PDF format.

A number of presentations about project results have been made at state, regional, and national meetings. The presentation and report below can be viewed in PDF format.