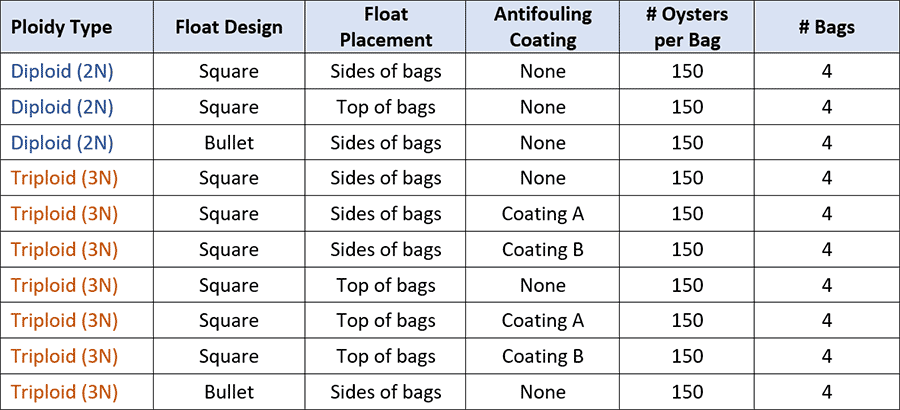

The second phase of the demonstration project evaluates the performance of diploid and triploid oysters planted in early spring, as opposed to the first phase in which oysters were planted in late summer. In addition to seed provided to participants in March (see previous article), oysters of each ploidy type were field nursed by the UF project team at their experimental lease off Cedar Key in April. At that time, diploids were 29 mm in shell height (SH) and triploids were 34 mm. Oysters were stocked into 9 mm mesh Vexar bags at densities of 700 per bag. After seven weeks, diploids averaged 39 mm in SH and 9 grams in weight, while triploids averaged 48 mm and 17 grams, respectively. On June 7, the larger seed were restocked into 14 mm mesh Vexar bags at a density of 150 per bag. To further examine the effects of float design and placement on oyster production and fouling control, the following gear types and management practices are being tested. In addition, two commercially available, biocide-free, antifouling coatings were applied to some of the oyster bags.

Summary of UF Growout Study initiated in June 2017

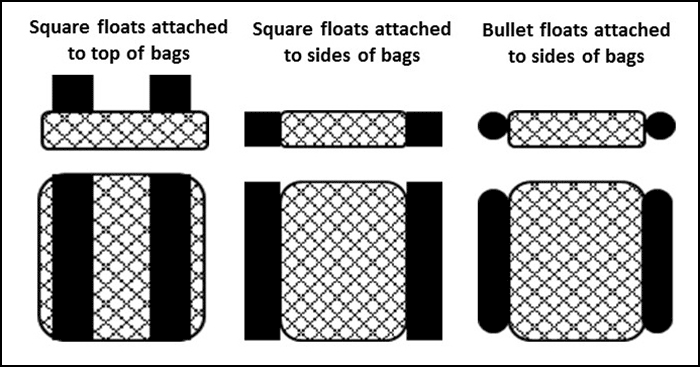

Weekly, all oyster bags will be flipped so that one side of the bag is exposed to air for drying of fouling organisms. During the summer, bags will be flipped in late afternoon, so that oysters are exposed over night when air temperatures are cooler. Bags in which the 4 ½” square floats are placed on top of the bags must be flipped back after exposure. Bags supported by floats, both square and cylindrical or “bullet”, attached on the sides of bag do not have to be “flipped back” after drying. If this is effective in controlling fouling, it will result in labor requirements being reduced by half. Two of the four replicate bags from each treatment will be sampled to estimate oyster growth and survival after 7-8 weeks, while the other two will be sampled after 14-16 weeks. It is anticipated that oysters in this study may be ready to harvest by October or November.

Top picture: Schematic of type and placement of floats to support oysters in 14 mm mesh Vexar bags.

Middle picture: Oyster bags with bullet (background) and square (foreground) floats attached to the sides of bags. Note bags that are white have been coated with biocide-free, antifouling coatings.

Bottom left picture: Oyster bags supported with square floats attached to the tops of the bags.

Bottom right picture: Oyster bags with square floats flipped up for aerial drying.

![]()